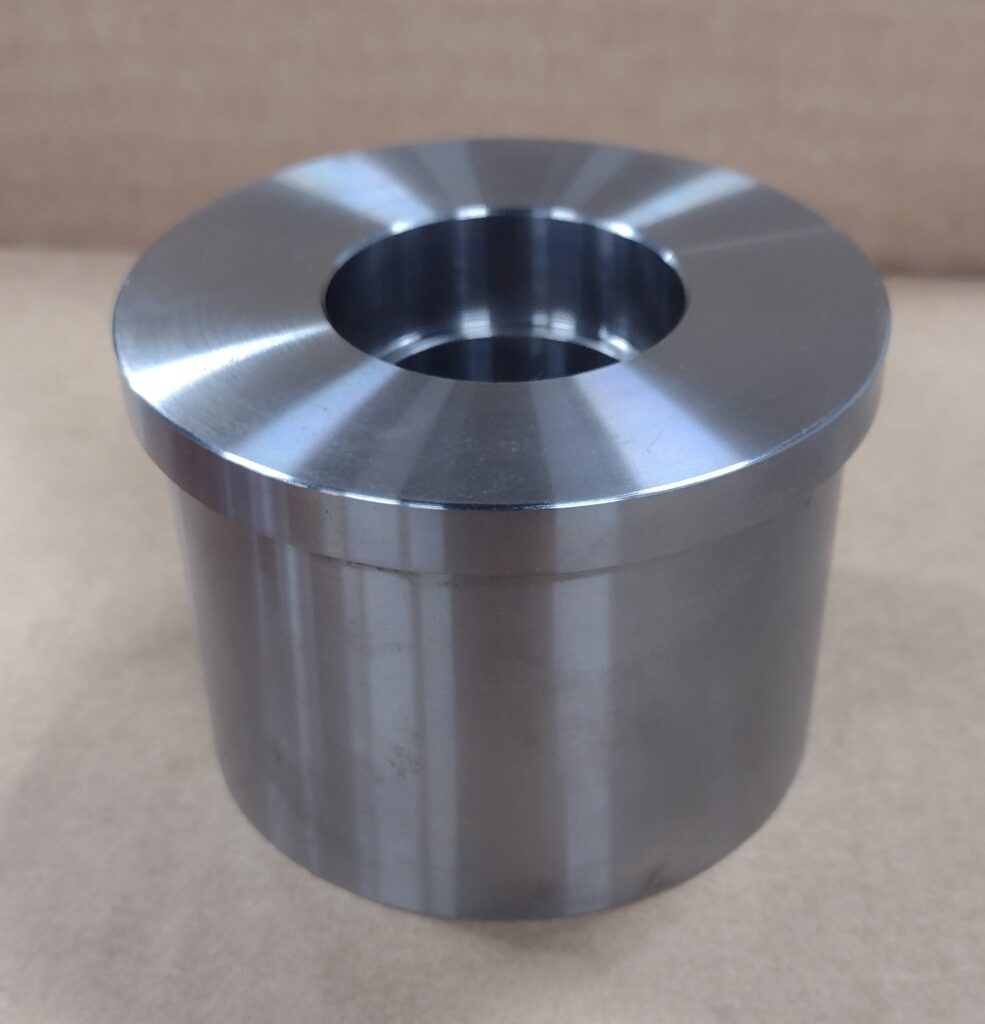

Often a part we make at Micron is not only functional, but visually striking as well. This self-lubricating hub is one of those parts.

The final version of this part is the product of three components — a housing and two bushings. We prepare the components separately and then assemble them into the part pictured above. Then we machine it once again to finish the process.

This hub and its components undergo several operations, which makes it an exciting part to see from start to finish.

Creating the housing

To create the housing, we first machine the raw material to create a rounded blank.

After Micron has blanked out the housing, we then mill it to shape the outer diameter and create the part’s four threaded holes.

Finally, one of our local vendors coats the housing in black oxide, which provides protection from corrosion and gives the part it’s distinctive coloration.

Specialized bushings

The bronze bushings are the second component in this assembly.

We machine these bushings from oil-impregnated, sintered bronze. Sintering, a process in which a material is formed by compressing small pieces or flakes together, makes the metal porous. As friction wears the bushing down, the pores in the metal open and release oil that re-lubricates the surface.

Bringing it all together: The self-lubricating hub

Once both parts are complete, we assemble them into the self-lubricating hub. We machine the assembled version once more to ensure that the inner diameters of the bushings are both concentric and conform to the required tolerances. This allows the part to rotate smoothly around a central axis.

And that marks the completion of a part that is both exciting to make and a source of pride for Micron.

If you are interested in requesting a quote from Micron or if you are interested in careers at Micron, please don’t hesitate to contact us.

Recent Comments