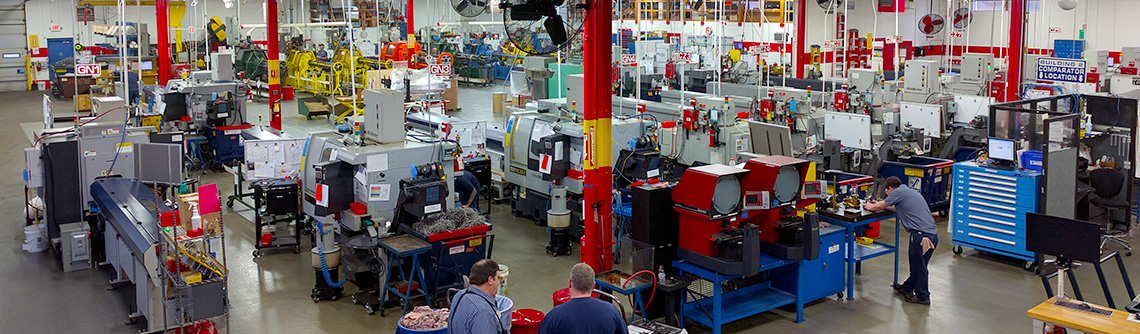

Machining Capabilities

Micron precision machining capabilities

Micron has effectively combined Lean principles, Continuous Improvement, and Design for Manufacture. We call our unique and productive approach systemicron™.

Micron precision machining capabilities

Micron has effectively combined Lean principles, Continuous Improvement, and Design for Manufacture. We call our unique and productive approach systemicron™.

Micron’s precision machine shop, unlike other CNC machining companies, offers milling operations, precision turning, sub-assembly and CNC prototyping resulting in a standardized, repeatable process that produces quality, ready-to-use parts.

We can machine your parts whether your material is aluminum, brass, bronze, copper, plastic, stainless steel, or steel. Because of our design for manufacture expertise, we can offer precision machined parts that present manufacturing challenges, in low to mid-volumes or are unusual shapes. We also extend our services with product design engineering services and our inventory management system.

Turning

Micron’s turning capabilities include state-of-the-art equipment including CNC lathes with both conventional and Swiss turning, also known as sliding headstock machines, designed for “long and skinny” parts, typically greater than 3:1 length to diameter ratio or larger. Micron offers a variety of equipment to produce the best results for each project. We offer bar capacity from 1/8″ to 2″ diameter including chucking capabilities up to 3.4″.

Milling

Micron offers milling for simple to highly engineered, complex precision machined parts. CNC vertical milling machines and lathe milling machines provide milling capabilities that others don’t. These capabilities result in milling machine parts that are standardized and cost effective.

Light Assembly

Micron offers sub-assemblies using components machined on our turning and milling centers.